Process Data Acquisition and Control

- Zoom

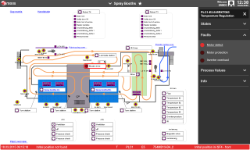

- Visualization of a conveyor system

As a systems supplier, Eisenmann integrates the complete plant control technology from one source. The problem of having to deal with a variety of interfaces does not arise. Our competent specialists have years of experience in the following fields:

- Project planning/ creating functional requirements

- Circuit diagram design and the manufacture of control cabinets

- Creating software for PLCs and visualization systems

- Material flow control, process control systems and the connection to customer ERP systems (E-MES)

- Commissioning, on-site production support and training

Due to extensive planning and counseling, concepts can be taken into account as early as in the project planning and tender preparation stages that result in a plant that is easy to maintain, energy efficient and economic.

To reduce downtimes, Eisenmann offers a remote maintenance option for all important control components.

Eisenmann Manufacturing Execution System E-MES

- Zoom

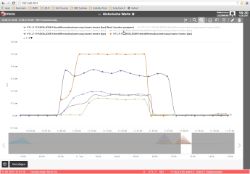

- Example for the visualization of an oven temperature profile in E-MES

- Example for the visualization of an oven temperature profile in E-MES

The Eisenmann Manufacturing Execution System (E-MES) is a browser-based production control system connecting the entire production facility – both horizontally, i.e. across the manufacturing process, and vertically, i.e. throughout all levels, from ERP down to shop floor IT. Due to integrated data capture, analysis and visualization E-MES ensures complete transparency, and can be used variably from simple operator control and monitoring system to a modular MES solution.

All data is accessible to users anywhere, at any time – no clients need to be installed. As a result, both the production and the maintenance staff on site, as well as colleagues and managers from anywhere in the world can monitor plant and equipment from a laptop, tablet, smartphone or smart-watch.

By means of user-defined key performance indicators, E-MES provides crucial information and insights – allowing users to critically review past manufacturing processes and make better decisions going forward.

E-MES is designed around a platform-independent, modular structure: further functionality modules can be added later in line with specific requirements. The E-MES portfolio offers made-to-measure solutions for every customer, from user-friendly operation and monitoring to high-level planning and control functionality. The production control system is configured in accordance with the specific requirements of the customer’s production facilities.

For more information, please visit: www.enisco.de

Eisenmann

Eisenmann